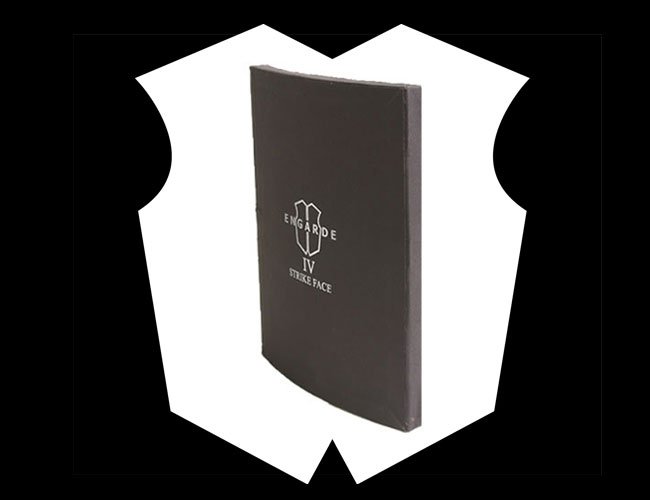

SAPI platesThe technology used for the material from which armor inserts for protective garments are made can quite legitimately be labeled "space age." This range of materials has been developed to produce the highest levels of protection, along with the lightest, thinnest panels possible. Two names that have become synonymous with high performance in the field are Spectra and Dyneema armor inserts. Developments in Armor Inserts Technology So the focus of continuing research is on further reducing the bulk and weight of the garment in general, while increasing mobility as much as possible. This could only be further improved if the technology also resulted in body armor being available at a much lower price. At the moment, a basic combat vest along with the necessary armor inserts can be a very expensive piece of equipment. Dupont, the makers of Kevlar, which is the fabric used for most of the protective clothing in use by the armed forces and security forces, is developing their most amazing protection system yet. They have named it Liquid Armor because it does not involve the use of rigid armor inserts at all. Instead, the fabric is soaked in a special fluid prior to being cut and sewn. It can also be molded, or whatever is necessary to produce the required shape. Liquid armor is easy and lightweight to wear. It protects the wearer by forming a rigid shield if it comes into contact with a projectile, hence its name, liquid armor. There are some combat situations where nothing but the highest level IV body armor will do. This level of protection is designed to protect the wearer against high velocity rifles and other threats, such as those from a blunt instrument. Body armor with this degree of protection is often a level IIIa vest fitted with the special plates designed to supplement the existing level of protection and raise it to a level IV. It is important to realize that even with level IV body armor, there is no way of rendering yourself completely resistant to any kind of ballistic or stabbing attack. Wearing any level of protection will increase your odds, but that is all. Even a level IV will fail if an assailant gets a "lucky hit." It is important to point this out because some private citizens tend to regard body armor as the complete answer, when there is no complete answer to the problem of violence. New Level IV Body Armor The liquid body armor is a response to DSM and Honeywell Spectra plates, but is not available at the moment. Armies all over the world are shifting from their bulkier ceramic plates to the new DYNEEMA/Ceramic combination. These new Level III and IV inserts have carefully been tested the last 8 years. They have put plates on the rooftop of buildings (in the sun, rain) and tested them after years and they still have the same performance. The liquid armor will need to be tested for some time now before being introduced to the public.

|